Revealing hot tearing mechanism for an additively manufactured high-entropy alloy via selective laser melting

Résumé

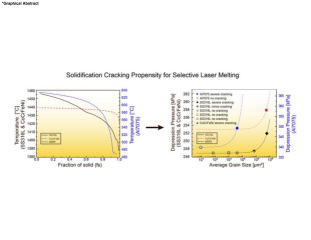

Hot tearing mechanisms of a high-entropy alloy CoCrFeNi additively manufactured by selective laser melting have been investigated. Intergranular solidification cracks are present regardless of various parameters used, suggesting poor laser-based printability for the alloy. Elemental segregation does not exist at the grain boundary that favours the solidification cracking. We find that severe residual stress induced by the large grain size is the root cause for the intergranular cracking. The classic Rappaz-Drezet-Gremaud model is used to predict the characteristic depression pressure limit beyond which hot tearing will occur for the selective laser melting of metals and alloys.

Domaines

Matériaux

Fichier principal

2019_Sun_SM_hot tearing additive manufacturing AlxCoCrFeNi high-entropy alloy.pdf (641.59 Ko)

Télécharger le fichier

2019_Sun_SM_hot tearing additive manufacturing AlxCoCrFeNi high-entropy alloy.pdf (641.59 Ko)

Télécharger le fichier

| Origine | Fichiers produits par l'(les) auteur(s) |

|---|